Paintless Dent Repair (PDR) has transformed auto collision repairs since its emergence in the 1980s, offering significant PDR advantages. This technique allows technicians to remove dents and scratches without painting or extensive panel replacement, resulting in faster turnarounds, reduced costs, and minimal damage traces. Its environmental benefits, including less waste and resource consumption, make it an eco-friendly choice. PDR experts also offer tire services and other minor repairs, making them a comprehensive solution for various vehicle concerns, ultimately driving its widespread acceptance in both independent garages and large automotive franchises.

The auto repair industry has witnessed a quiet revolution thanks to Paintless Dent Repair (PDR) techniques, which have transformed how businesses operate and customers perceive vehicle damage repairs. This article delves into the rise of PDR, exploring its historical roots and rapid adoption within the sector. We uncover the key benefits that make PDR advantageous for both businesses and customers, from cost savings to enhanced satisfaction. Additionally, we discuss how technological advancements and environmental considerations are driving PDR’s future in modern auto repair, ensuring its enduring relevance.

- The Rise of PDR and Its Impact on the Auto Industry

- – A brief history of PDR (Paintless Dent Repair)

- – How PDR advantages caught on in the auto repair sector

The Rise of PDR and Its Impact on the Auto Industry

The concept of Paintless Dent Repair (PDR) emerged as a game-changer in the automotive industry, transforming how auto collision repairs and car bodywork services are approached. What was once a niche process has evolved into a widely recognized and sought-after method for fender repair and dent removal. PDR advantages have become evident, offering both businesses and customers a more efficient, cost-effective, and environmentally friendly solution compared to traditional auto body repair methods.

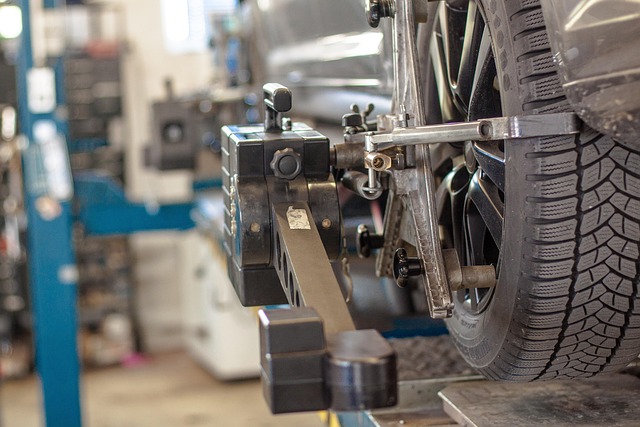

This innovative technique allows technicians to fix dents, creases, and dings without the need for sandpaper, paint, or extensive panel replacement. By utilizing specialized tools and trained expertise, PDR can restore vehicles to their original condition, leaving minimal traces of damage. As a result, the auto industry has seen a rise in customer satisfaction and a decrease in repair costs, making it an attractive option for both independent garages and large automotive franchises.

– A brief history of PDR (Paintless Dent Repair)

Paintless Dent Repair (PDR) has emerged as a game-changer in the auto repair industry, transforming how car bodies are restored and bringing numerous advantages to both businesses and customers alike. This innovative technique has been steadily gaining popularity since its inception in the 1980s, offering a cost-effective and efficient solution for minor cosmetic damage. PDR specialists utilise specialised tools and techniques to remove dents, scratches, and dings without the need for traditional painting or extensive body work.

By mastering PDR, auto repair shops can provide quick turnarounds on car body restoration, appealing to customers seeking efficient and affordable solutions. This method also reduces the environmental impact of auto maintenance, as it minimises waste and the consumption of resources compared to conventional painting processes. Additionally, PDR experts can often perform tire services and other minor repairs, making them a one-stop solution for various vehicle concerns, from dents to flat tyres.

– How PDR advantages caught on in the auto repair sector

In the ever-evolving landscape of auto repair, the adoption of PDR (Paintless Dent Repair) advantages has been nothing short of transformative. Initially met with skepticism, PDR gained traction as technicians recognized its numerous benefits. Unlike traditional methods that often involved extensive painting and labor-intensive processes, PDR offers a more efficient, cost-effective solution for various cosmetic dents and scratches. This non-invasive approach not only reduces downtime for vehicle owners but also minimizes expenses for collision centers.

As the demand for quick, high-quality repairs grew, so did the professionalization of PDR services. Advanced tools and techniques have refined the process, making it possible to restore vehicles to near-original condition. The appeal extends beyond economic considerations; PDR’s ability to preserve original factory finishes without exposure to additional chemicals or potential contamination from paint mixing has made it a preferred choice for eco-conscious consumers. This shift towards green initiatives further propelled the integration of PDR advantages into the mainstream auto repair sector, solidifying its place in modern collision centers and auto glass repair shops.

The adoption of Paintless Dent Repair (PDR) technologies has undeniably revolutionized the auto repair industry. By leveraging advanced tools and techniques, PDR advantages have transformed how businesses operate, offering faster turnaround times, reduced costs, and higher customer satisfaction. As the demand for efficient and cost-effective repairs continues to grow, embracing PDR advantages will remain a strategic decision for auto repair shops, ensuring they stay competitive and meet modern consumer expectations.